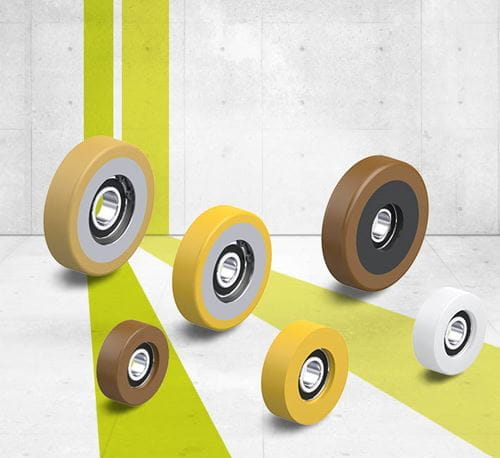

Blickle guide rollers for every application

Keeping the world moving

Guide rollers keep things moving smoothly in a number of different areas and help to transport loads safely by making sure that they always follow the same linear path along a guide or rail.

Guide rollers keep things moving smoothly in a number of different areas and help to transport loads safely by making sure that they always follow the same linear path along a guide or rail.

They are used for a wide variety of applications, both indoors and outdoors:

- in sorting facilities (airport luggage sorting, packet sorting, logistics centres)

- as guide elements in machines

- in production plants

- in lifts and escalators

- in conveyor belts

- in offshore cranes

Generally speaking, guide rollers come in two different varieties: guide wheels and running wheels. Guide wheels are used in machines or gates to facilitate linear motion. These wheels are usually put under frequent but brief loads. Running wheels, on the other hand, are usually designed to withstand constant loads. They are frequently used in conveyor systems.

A wide range of products to suit any requirements

Guide rollers have to meet a wide range of different requirements in various areas. We use different wheel centre materials and our internally developed treads to suit diverse applications. Machinery and equipment require low levels of rolling resistance to keep things moving smoothly and efficiently. Blickle Extrathane® tread is perfectly suited for this application, due to its low rolling resistance and high degree of resistance to abrasion. Guide rollers which are used outdoors have to withstand fluctuating temperatures and extreme weather conditions. They also need to be corrosion-resistant. The FPOB castor series, which uses our internally developed Besthane® tread and a nylon wheel centre, is a perfect match. The tread provides a low level of rolling resistance and makes equipment quiet when in motion. The castors in this series are also flexible at low temperatures, hydrolysis-resistant and capable of transporting heavy loads of up to 375 kg. This makes them perfectly suited to outdoor applications. Guide rollers used in the chemical or pharmaceutical industries also need to be electrically conductive and resistant to chemicals. We have versions which meet these requirements.

In the majority of our series, the tread of the wheel is cast or applied directly onto the ball bearing or wheel centre. This makes the guide rollers extremely resilient due to the strong chemical bond between the tread and the bearing or wheel centre.

The right product for any application

Blickle provides a total of seven different guide roller series with different polyurethane and nylon treads as part of our comprehensive standard range.

An overview of these series is provided below, along with information about their special features and the areas in which they are used.

| Series | Description | Wheel Ø | Load capacity | Versions | Special features | Applications |

|---|---|---|---|---|---|---|

|

Series FTH: Blickle Extrathane® polyurethane tread, cast directly onto the ball bearing |

30 – 75 mm | 25 – 150 kg | corrosion-resistant ball bearing (on request) |

|

|

|

Series FSTH: Steel wheel centre, tread cast directly onto the steel wheel centre, pressed-in ball bearing |

40 – 125 mm | 60 – 375 kg |

|

|

|

|

Series FPOB: Nylon wheel centre, Blickle Besthane® polyurethane tread |

80 – 125 mm | 160 – 375 kg | corrosion-resistant ball bearing (on request) |

|

primarily for outdoor use:

|

|

Series FPTH: Nylon wheel centre cast onto the ball bearing, thermoplastic polyurethane tread cast onto the wheel centre |

60 – 125 mm | 110 – 290 kg |

|

|

primarily for outdoor use:

|

|

Series FPU: Guide roller with thermoplastic polyurethane tread

|

25 – 60 mm | 15 – 100 kg |

|

|

|

|

Series FPO: Nylon 6 tread cast directly onto the ball bearing |

25 – 125 mm | 40 – 530 kg |

|

|

primarily for outdoor use:

|

|

Series FSVU: Guide roller with polyurethane tread Vulkollan®, with steel wheel centre |

40 – 100 mm | 70 – 250 kg |

|

|

|

Are you looking for a specific product? Use our product finder! You can use a variety of filters to find the guide roller you need.

Blickle quality products Made in Germany

We use our own facilities to develop and manufacture our polyurethane treads and the injection moulding process. Blickle has developed a variety of polyurethane types for different applications. Tread and tyre hardness, abrasion, load capacity, rolling resistance and many other characteristics vary depending on the material composition, providing a great deal of versatility. We also use our in-house facilities to manufacture a wide range of synthetic wheels and wheel centres from nylon, polypropylene, thermoplastic rubber-elastomer (TPE) and thermoplastic polyurethane (TPU). We also produce heat-resistant, electrically conductive and glass fibre-reinforced versions.

Having our own manufacturing facilities gives us complete control over quality and delivery dates. It also allows us to react with speed and flexibility to customer requirements.

More information about Blickle’s manufacturing facilities is available here.

Special requirements? No problem.

If you cannot find the guide roller you are looking for in our standard range, we would be happy to develop a special solution for you. This might involve simply making some minor modifications to a castor in our standard range. We can also develop new products to meet customer requirements. You can find examples of the special versions we have provided for a wide range of customers in our Success Stories.

Do you have any other questions? Your personal contact partner will be happy to help you select the right product!