More heavy loads safely

Extensive portfolio of Blickle heavy duty wheels and castors

Whether it's at the airport or in the production hall: special transport platforms are often needed to move extremely heavy loads. The right underlying components are critical. Robust wheels and castors are necessary to get the "bulky stuff" moving. Blickle offers an extensive portfolio of heavy duty wheels and castors that can handle loads of up to 100 tonnes.

A new flagship in heavy duty castors is the welded steel heavy duty double-castor, LSSD-GSPO 500K with a load capacity of up to 30 tonnes. It is equipped with heavy duty compressed cast nylon wheels, which offer low rolling and swivel resistance, especially on smooth floors. In addition to its compact design, the heavy duty castor sets itself apart through extremely high rigidity. The swivel head used here is particularly robust and has a four-point swivel bearing.

Typical fields of application for heavy duty wheels and castors include:

- rack feeders

- industrial trucks

- assembly and transport systems

In order to ensure that the transport runs smoothly, without shocks, and that the goods reach their destination without being damaged, spring-loaded castors are also available. These provide excellent spring and damping characteristics and are specially designed for the respective application. Upon customer request, solutions can be created that are specially tailored to the respective application. "For heavy duty applications, we continuously encounter the challenge of combining very high load-bearing capacities with a compact design," reports Thomas Zimmer, head of the heavy duty wheels design department at Blickle. "Our customers attach great importance to a high level of operational comfort. That is why we are seeing the trend moving away from steel and cast wheels and toward wheels with polyurethane tread, which also helps protect the floor surface."

Custom-made solutions for the aviation industry

One example of this are the welded steel Blickle LSD-SETH heavy duty castors, special versions with an extended axle for fine positioning of the tripod jack under the aircraft, used on the HYDRO tripod jack with a capacity of 110 tonnes. As an industry leader, HYDRO has been developing products and projects for the production and maintenance of aircraft and engines for more than 50 years. In the area of ground support equipment, the company's tripod jacks enable particularly economical and highly efficient aircraft maintenance, covering the entire spectrum of aviation with a capacity of between two and 210 tonnes. "Our customers tow our tripod jacks over long distances and at high speeds, sometimes over poor surfaces to their place of work," says Pamela Lanzillotti, Head of Business Unit Ground Support Equipment at HYDRO. "That's why we were looking for special castors with low rolling resistance and ended up developing a special suitable solution with Blickle."

Four-fold castor for use with modular transport systems

In another aerospace application, Blickle's welded steel heavy duty four-fold castor provided the right solution. The client was looking for a swivel castor with a foot guard for transporting heavy and sensitive aircraft components, one that could also clear away small debris from its path. As the load is shifted manually, low rolling resistance was also important. Blickle developed a welded steel heavy duty castor with a robust swivel head for this application. The relatively low mounting height allowed for high bracket stability. By using four wheels per castor, the load is spread out over a large area for smoother rolling. To achieve low rolling resistance, Blickle used a cast wheel centre with a tread made of the high-quality polyurethane elastomer Blickle Extrathane® which also protects the floor surface. The castors were equipped with a foot guard to provide protection against injuries caused by wheels or by objects thrown up into the air. A scraper made of polyurethane also pushes smaller items out of the way and thus ensures a smooth, jerk-free ride.

A heavy duty four-fold castor with suspension was developed by Blickle engineers for use in modular individual transport systems that move loads of up to 500 tonnes. In order to distribute the load across a larger surface area, the Blickle customer needed supporting castors for its transport systems in addition to the drive wheels. These each needed a load capacity of five tonnes and had to be spring loaded to compensate for bumps. The heavy duty castor designed specifically for the customer, equipped with two polyurethane springs and four grey cast iron wheels Blickle Besthane® polyurethane tread, fully met the requirements of the desired application.

Heavy duty drive castor boasts enormously high load capacity

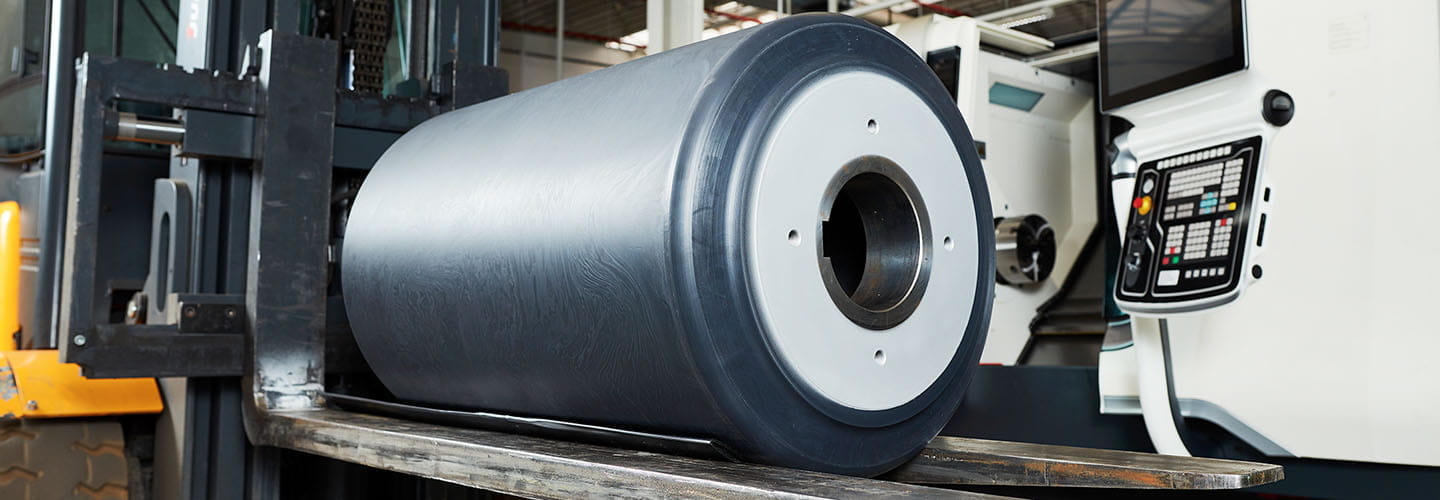

The heavy duty drive castor with Blickle Extrathane® polyurethane tread also sets new standards. It carries up to 100 tonnes, nearly 25 percent more than four individual wheels. In addition to the high load-bearing capacity, the Blickle solution offers more safety with less installation effort required on the part of the customer. Due to the optimal distribution of force, a thinner wheel axle can also be used, which leads to further cost savings.

Would you like to review the features of our heavy duty wheels and castors? Click here for our animated presentations!