Heavy duty swivel castors from Blickle

Above and beyond – in both load capacity and speed

Swivel castors used in heavy duty applications also come in a wide range of versions. The load capacity of the heavy duty swivel castors is up to 30,000 kg and the wheel diameter up to 500 mm with a maximum mounting height of 675 mm. Upon customer request, Blickle can also produce custom-fit special solutions for applications around the world. A small selection of special solutions that have already implemented can be found in the Success Stories section.

In addition to applications involving heavy loads, heavy duty swivel castors are also used at higher speeds of up to 25 km/h. Compared to swivel castors in the light duty segment or in transport technology, they are built particularly sturdy in order to be able to move what are sometimes very heavy loads. Swivel castors with two wheels, so-called twin wheel castors, are also sometimes used in this area. Typical areas of application include industrial trucks, assembly and transport systems or indoor and outdoor installations of many different types.

All heavy duty wheels and castors from Blickle are tested according to the test conditions of the relevant DIN regulations - at 4 km/h according to DIN EN 12532, at higher speeds according to DIN EN 12533.

Heavy duty swivel castors: The right heavy duty swivel castor for every application

Steerable heavy-duty castors are suitable for different applications depending on the tread:

Heavy duty swivel castors: Polyurethane

The polyurethane wheels, for example, impress with high cut and tear propagation resistance, low rolling resistance, high dynamic load capacity and very good floor surface preservation.

Heavy duty swivel castors with elastic solid rubber or super-elastic solid rubber tread

Alternatively, heavy duty swivel castors with elastic or super-elastic solid rubber tyres and a steel rim are available. Compared to pneumatic tyres, this steerable heavy-duty castor series guarantees puncture-proof, maintenance-free operation under normal application conditions and good stability with precise steering behaviour.

Heavy duty swivel castors: compressed cast nylon or nylon

Steerable heavy duty castors with compressed cast nylon or nylon wheels, on the other hand, are extremely impact resistant and have a particularly high load capacity. They are especially suitable for smooth surfaces and delight users with their smooth rolling and very low roll and swivel resistance. With the LSSD-GSPO 500K, for example, it is possible to achieve a load capacity of 30,000 kg.

Heavy duty swivel castors: solid steel

If a high load capacity is required, your best choice is suitable heavy duty castors with wheels made of solid steel. With these, loads of up to 15,000 kg per castor are no problem. If you are looking for swivel castors for use at high temperatures instead, Blickle offers versions with grey cast iron wheels for heavy duty applications. These can be used at ambient temperatures of up to 270 °C.

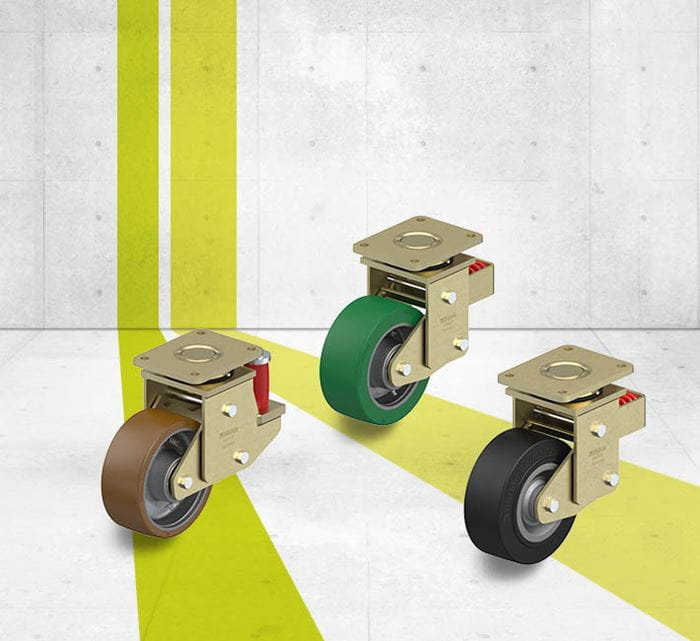

Heavy duty swivel castors: Spring-loaded heavy duty castors

Our spring-loaded heavy duty swivel castors are the ideal solution for transporting heavy loads in various industrial environments. Thanks to their robust construction and resilient properties, they enable precise and effortless steering, even under extreme conditions. Our heavy duty swivel castors are specially designed to handle high loads and offer reliable manoeuvrability on various surfaces.

Heavy duty swivel castors: Compact castors

To complete this list, we must also mention the "mighty mites": our mini heavy duty castors. Although the load capacity does not compare to the previously mentioned wheel series, their load capacity of up to 350 kg is still very impressive for the 35 to 65 mm wheel diameter and total height of 52 to 90 mm. Compact castors combine a low mounting height with high load capacities. As a twin wheel swivel castor, the load capacity can even be more than doubled. You can find an overview of the compact castors in our online catalogue.

Have you lost track of all of the heavy duty swivel castors? Then perhaps the Blickle product finder can assist you in your search. This allows you to filter for product-specific properties and thus reduce the large selection to just a few relevant products. Otherwise, your personal advisor will be happy to assist you with the product selection during a telephone call.